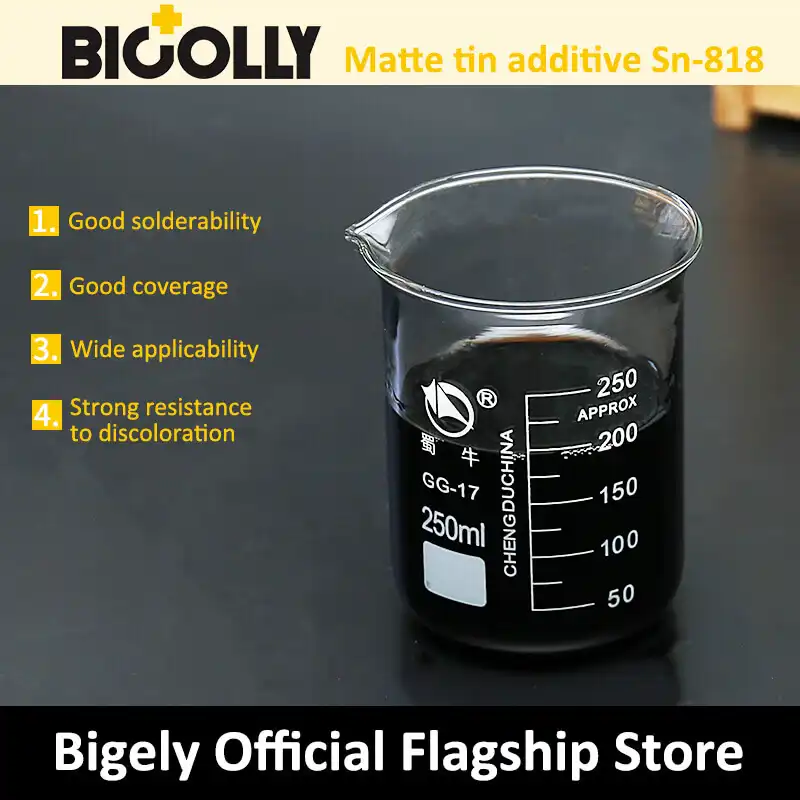

Chemical tin additive Sn-818

Features

1 , the coating dense, uniform.

2 , the coating has good defended , conductivity, ductility.

3 , cleaning is good, easily washed coating marks and residual material occur.

4 , the bath is not easy to turbidity, long service life.

5 , Suitable for chemical immersion tin on copper substrate.

Solution composition and operating conditions

|

Chemical tin immersion additives |

Original solution use |

|

temperature |

40±2℃ |

|

time |

5-30 minutes (depending on needs) |

|

Working load area) |

1-2dm2/L (that is , the plating carried by 1 liter of working fluid |

|

Stir |

Mechanical stirring |

|

Continuous filtration the amount |

The filtration capacity per hour is not less than 6 times the working fluid volume

|

|

material |

PP plastic or FRP |

Manufacturer of high-quality electroplating additives

plating tank process

![]()

Grooves respectively set to the temperature of the time between

![]()

|

Clean clean tank water washing tank Washing tank |

Acid cleaning fluid Deionized water Deionized water |

40 ℃ Room temperature Room temperature |

1-5 minutes (as needed) 30 seconds

30 seconds |

|

Micro-etching groove |

H 2 SO 4 -Na 2 S 2 O 8 |

Room temperature |

1 minute |

|

Washing tank |

Deionized water |

Room temperature |

30 seconds |

|

Washing tank |

Deionized water |

Room temperature |

30 seconds |

|

Acid leaching tank |

Alkyl Sulfonic Acid 5% |

Room temperature |

30 seconds |

|

Washing tank |

Deionized water |

Room temperature |

30 seconds |

|

Washing tank |

Deionized water |

Room temperature |

30 seconds |

|

Chemical immersion tin bath |

Chemical tin immersion additives |

40 ℃ |

5-30 minutes (depending on the need for a) |

|

Washing tank |

Deionized water |

Room temperature |

30 seconds |

|

Washing tank |

Deionized water |

Room temperature |

30 seconds |

|

dry |

\ |

\ |

\ |

solution maintenance

1. Use chemical tin immersion additives to replenish tin immersion liquid to bring out the loss.

2. Copper impurities in the plating solution will hinder the reduction of tin, and control it to be less than 5 g / l . Can be a small current through the electrolysis, copper female five -pole analysis , the points in addition to analysis off side . Method (content of tin )

Medicines

(1) Dilute hydrochloric acid ( 6N ) : Concentrated hydrochloric acid and water ratio 1 : 1

(2) Starch indicator: 1g of soluble starch , dissolved in boiling water to 100ml . Boil for another minute.

(3) 0.1N iodine standard solution: weigh 12.7g of iodine refined by sublimation . Add a small amount of water to dissolve 40g of potassium iodide , then add water to dilute to 1L .

Analysis operation

(1) Take 5ml of plating solution

(2) Add 100ml of water

(3) Add 20ml of dilute hydrochloric acid (6N)

(4) Add 5ml starch indicator

(5) Use 0.1N iodine standard droplets until the solution turns blue-purple, and consumes volume V ml.

Calculation

Disclaimer: All suggestions on our products in this technical data are based on the experiments and data trusted by our company as the standard. Practitioners in each country and set up operations vary on equipment, so the company can not guarantee and be responsible for any adverse consequences. All the information in this troubleshooting method cannot be used as evidence of copyright infringement.

Chemical tin additive FAQ

1. Q: Do you make the products yourself? Are you a trader or a manufacturer?

A: Yes, the products are produced by our company. Our company is a manufacturer focusing on the R&D and manufacturing of environmental protection electroplating additives. Our factory has 5000 square meters with an annual capacity of 15000 tons.

2. Q: Can your company send samples for trial?

A: We can provide samples for trial.

3. Q: What is the quality of your products?

A: Our company all products core raw materials is used by Germany BASF, American Dow Chemical and other international brand products. The production process is strictly in accordance with the ISO9001 quality management system, from the incoming inspection, product inspection, according to the strict inspection standard, ensure that every drop of products qualified. Product quality you can rest assured, like BYD, Huawei, Foxconn such enterprises are also using our products.

4. Q: How long is the shelf life of your products?

A: The shelf life of our products is two years. If you do not use up the products within a short time after you buy them, we suggest you store them in a cool place, not in the sun or in a high temperature environment.

5. Q: Are your products environmentally safe?

A: Our products have passed the SGS test and are recognized as "Green and Environment-friendly Promotion Products". Many auto parts and electronic products which use our products can pass the strict environmental protection test when they are exported to Europe and America. Therefore, we can be trusted in terms of environmental protection and safety.

6. Q: Can your company provide technical services?

A: Yes, our company has a technical service team of more than 10 people. The technical engineers all have more than 20 years' experience in electroplating factory. They can provide customers with comprehensive technical of pre-sales and after sales.

7. Q: Is it possible to visit your company?

A: Yes, of course. You are very welcome! We can meet you at Jieyang airport, If you can come to our city. Also you can visit our factory through live video.

8. Q: Can you customize products according to our needs?

A: Yes, our company has research and development strength, the product formula derived from Europe and the United States laboratory, European and American engineers technical support, work together with domestic universities. Our company has a member of Guangdong province expert enterprise workstation, Shantou university science and technology correspondent workstation, Jieyang city environmental protection engineering research center for electroplating additive.Therefore, it can meet all kinds of customized requirements proposed by customers.

Products

Products