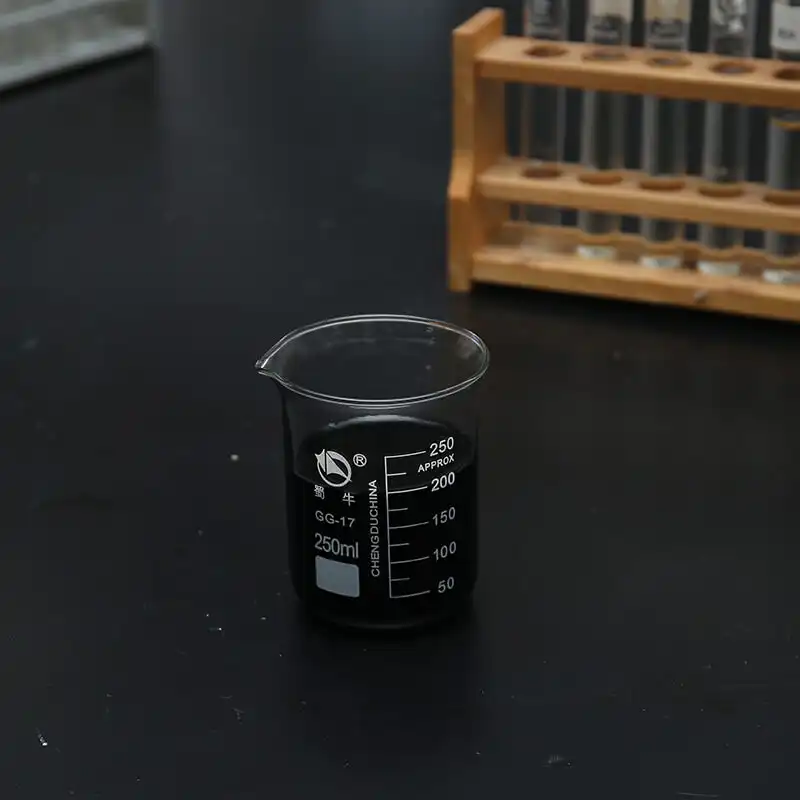

| Product Name: Zinc-nickel alloy trivalent chromium blue-white passivator | Packing specification: 25kg/barrel |

| Product appearance: Reddish brown to dark purple liquid | PH value: 1.0-6.5 |

| Specific gravity: 1.05-1.18 | Solubility in water: all dissolved |

| Storage method: Ventilated and dry place | Shelf life: 2 years |

Instructions for use

|

Zn-323A |

15-50ml/L |

|

Zn-323B |

50-100ml/L |

|

Temperature |

25-40°C |

|

Time |

20-60 seconds |

|

PH value |

3.5-4.5 |

|

Stir |

Mechanical stirring or air stirring |

| Drying | 60-80°C 10-25 minutes |

Product features

|

Does not contain hexavalent chromium

Green products, through SGS product testing and certification, meet ROHS, ELV regulatory requirements, use at ease

|

|

|

|

|

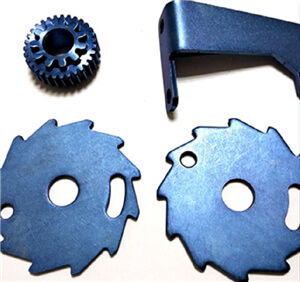

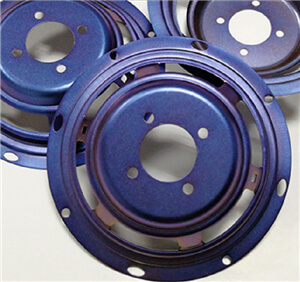

A bright and uniform blue passivation film can be obtained

Passivation film is not easy to turn yellow and does not fade

|

|

Good corrosion resistance

TBC active ingredients are added to the product, which has strong anti-rust performance. When the thickness of the coating layer is ≥ 5-8 microns, the resistance to NSS>350 hours can meet the functional requirements of auto parts

|

|

|

|

High temperature Resistance

The passivation film is baked at a temperature of 200°C, the appearance is rarely changed, and its NSS resistance can still exceed 350 hours)

|

|

|

Wide application PH range

PH value operating range is 3.5-4.5, wide process range, easy to operate and maintain

|

|

|

|

|

Superior impurity Resistance

High tolerance to iron impurities and zinc impurities, which can reduce the time of production shutdown and the loss of passivating agent, and save costs

|

Scope of application

FAQ

1. Q: Do you make the products yourself? Are you a trader or a manufacturer?

A: Yes, the products are produced by our company. Our company is a manufacturer focusing on the R&D and manufacturing of environmental protection electroplating additives. Our factory has 5000 square meters with an annual capacity of 15000 tons.

2. Q: Can your company send samples for trial?

A: We can provide samples for trial.

3. Q: What is the quality of your products?

A: Our company all products core raw materials is used by Germany BASF, American Dow Chemical and other international brand products. The production process is strictly in accordance with the ISO9001 quality management system, from the incoming inspection, product inspection, according to the strict inspection standard, ensure that every drop of products qualified. Product quality you can rest assured, like BYD, Huawei, Foxconn such enterprises are also using our products.

4. Q: How long is the shelf life of your products?

A: The shelf life of our products is two years. If you do not use up the products within a short time after you buy them, we suggest you store them in a cool place, not in the sun or in a high temperature environment.

5. Q: Are your products environmentally safe?

A: Our products have passed the SGS test and are recognized as "Green and Environment-friendly Promotion Products". Many auto parts and electronic products which use our products can pass the strict environmental protection test when they are exported to Europe and America. Therefore, we can be trusted in terms of environmental protection and safety.

6. Q: Can your company provide technical services?

A: Yes, our company has a technical service team of more than 10 people. The technical engineers all have more than 20 years' experience in electroplating factory. They can provide customers with comprehensive technical of pre-sales and after sales.

7. Q: Is it possible to visit your company?

A: Yes, of course. You are very welcome! We can meet you at Jieyang airport, If you can come to our city. Also you can visit our factory through live video.

8. Q: Can you customize products according to our needs?

A: Yes, our company has research and development strength, the product formula derived from Europe and the United States laboratory, European and American engineers technical support, work together with domestic universities. Our company has a member of Guangdong province expert enterprise workstation, Shantou university science and technology correspondent workstation, Jieyang city environmental protection engineering research center for electroplating additive.Therefore, it can meet all kinds of customized requirements proposed by customers.

Products

Products