Plastic electroplating acceleration agent

Plastic electroplating glue

Description: plastic plating deflocculant a Species specific dry matter of the mixture. When it is dissolved in water when , can activate pre-feed line of copper or of a nickel of the plastic surface. This product can provide a wide range of operating parameters , and is particularly suitable for bulky ABS and Noryl products .

Glue plastic plating solution having a good solution to reduce the impurity concentration of the metal capacity, because as if these impurities in concentrations up to a certain standard registration, would prevent the normal and complete acceleration.

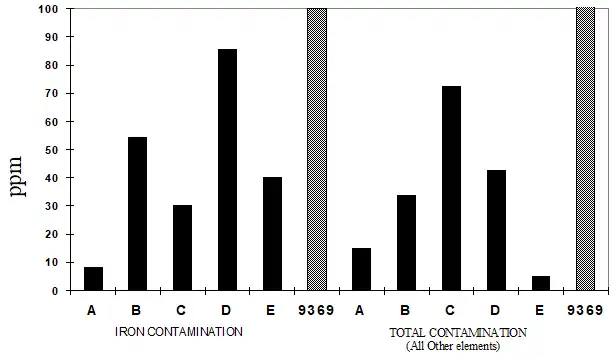

The following columnar FIG expressed relative to the metal content of the contamination, the contamination of a large number of conventional accelerating agent is not exist. This figure likewise discloses in the plastic solution plating material glue highest can tolerate contamination content of.

Build a bath

|

Plastic electroplating glue |

concentration |

|

It was dissolved in de- off sub-water |

60 - 90 G / L |

Add 3/4 operating volume of deionized water to the tank, heat to 49°C, stir with air, and slowly add the required amount of plastic electroplating degelling agent.

Plastic electroplating degelling agent cannot be used in hard water.

![]()

Operating conditions

|

temperature |

38-54°C |

|

time |

0.5~5 minutes |

|

Cl - concentration |

0.5N, @ plastic electrical plating glue solution (60g / L) |

![]()

Equipment

|

Tank : |

PVC, PP, PE |

|

Stir : |

Gentle air stirring |

|

Add hot : |

Teflon steam pipes plus hot quartz immersion plus heat is |

|

Convulsion : |

Built proposed use |

|

Filter : |

Requires the use of 5-10 micron filter element and covered with filter aid and activated carbon |

|

To remove particulate matter . Such use is to maintain a long the bath life and maximum operating range of the basic operation. |

|

![]()

General control and maintenance :

I. concentration

Pipette 10mL sample tank solution into a 250mL conical flask

Add 25mL pure water

Add 5 drops of phenolphthalein indicator

Titrate with 0.5N NaOH to the pink end point

Recording ml titration with number

Calculation : ml of N aOH×N of NaOH / 58 = plastic electroplating degelling agent

![]()

Keep at 60-90g/L

II Cl-Analysis

1. drawn to a bath 10mL capacity 100mL flask, dilute to the mark

2. quasi indeed absorb 5ml solution to 250 tapered vial

3. Add 100ml pure water and 3 drops of phenolphthalein indicator

4. Add 0.1N NaOH until pink appears

5. was added 3 drops of a saturated chromium acid sodium indicating agent

6. Titrate with 0.1N AgNO3 until the end point is reddish brown .

Calculate: concentration ml AgNO3×N AgNO3×1.7=Cl-

Cl- concentration should be maintained at 0.5~0.8N.

Security warning

For the health and safety from the see , Bi Gelai public Division recommends that customers / users before using refer Bi Gelai material safety data sheet. Material safety data sheets can be obtained from Bigley .

Wastewater treatment

Before treating wastewater according to Bigley 's wastewater treatment recommendations, users must understand the local laws and regulations regarding wastewater treatment methods inside and outside the factory. If our suggestions conflict with laws and regulations, the local laws and regulations shall prevail.

The pH was neutralized to 7 with sodium hydroxide .

Order information

|

Product |

packaging |

| Plastic electroplating debonding agent | 25kg/bag |

Products

Products