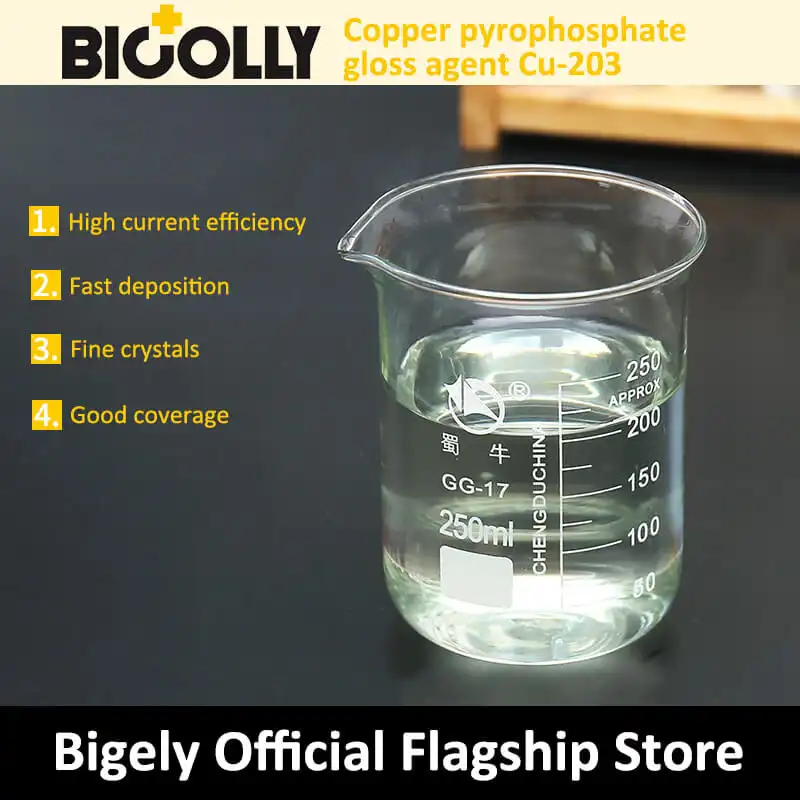

I-Copper pyrophosphate gloss agent

C u-203 i-copper pyrophosphate brightener

Incazelo : I-Cu-203 iyinqubo yethusi ekhanyayo ye-pyrophosphate, le nqubo ingakhiqizwa i-copper plating eluhlaza ekhanyayo futhi ebushelelezi, ikakhulukazi yokuhlobisa.

isici

· Ucwecwe lwethusi olukhanyayo futhi oluyisicaba

· Ukwakhiwa nokugcinwa kahle kwebhavu kulula

··Ingonga ungqimba olubizayo lwe-nickel lokucwenga ku-electroplating yokuhlobisa

· Ayikho i-cyanide

· Ifaneleka kakhulu i-zinc die castings

1. Amapharamitha okugeza

| ipharamitha |

range |

best value |

| Temperature℃ |

50-60 |

55 |

| Ukuminyana kwamanje ( Adm 2 ) |

3-6 |

3.5- 4 |

| pH |

8.6-9 .2 |

8.8 |

| I-ion yethusi ( g/L ) |

20-30 |

amashumi amabili nane |

| Ingqikithi P 2 O 7 4- ( g /L ) |

130-225 |

165 |

| Amonia ( g/L ) |

0.8-1.0 |

0.9 |

| P ratio |

6.4 : 1-7.5 : 1 |

Inqunywa ngu-Cu 2- |

2. Ukugcinwa koketshezi lokugeza

| okungeziwe |

Izinombolo |

Engeza imvamisa |

| Brightener |

Cu-203B |

1.7-2.5 amalitha ngo-10KAH |

| Opener |

Cu-203A |

Engeza ngemva kokugeza noma ukuhlanzwa |

| ammonia |

|

Engeza u-0.06ml/L we-ammonia enamandla adonsela phansi angu-0.880 njalo ngehora |

Copper & Potassium Pyrophosphate

Kubaluleke kakhulu ukugcina ukugcwala kwe-potassium pyrophosphate, ngaphandle kwalokho ukukhanya kobubanzi bokumbozwa kuzoncishiswa ngenxa yokushiswa kwezindawo eziminyanisa kakhulu zamanje kanye nokuba mnyama ezindaweni eziminyana zamanje.

Njengoba ukufakwa kwama-ion ethusi ne-potassium pyrophosphate kuhlobene eduze, imvamisa yokwengezwa kwezithasiselo ezilandelayo kufanele kubhekwe futhi kuhlaziywe:

Kunye nokuncipha kwe-ion yethusi ngo-1g/L, engeza u-2.82g/L we-pyrophosphate yethusi. i-trihydrate. Ngokwale ndlela yokwengeza, inani eliphelele le-pyrophosphate lingakhuphuka ngo-1.353g/L. Uma i-1g/L ye-pyrophosphate yethusi yengezwa , isamba se-pyrophosphate sizokwenyuka ngo-0.48g/L .

Uma i-pyrophosphate ingaphansi kwevelu elinconyiwe lika-1g/L , ungakwazi ukwengeza u-1.9g/L we-potassium pyrophosphate.

Uma umshini wokuhlaziya unezinto zokubala ezinganele, ukulandela isilinganiso esingu-3 : 1 (isilinganiso sesisindo) ukwengeza i-potassium pyrophosphate ne-pyrophosphate yethusi. izikhathi lapho ukuhlangana kwe-ion yethusi .

Isibonelo, uma ukuhlangana kwe-ion yethusi kungu-20g/L , ukugxila kwengqikithi ye-pyrophosphate kufanele kube ngu-128-150g/L . Uma ukugxiliswa kwe-ion yethusi kungu-30g/L , ingqikithi ye-pyrophosphate kufanele ibe phakathi kuka-192-225g/L .

ammonia

Engeza i-ammonia ukuze unxephezele ukulahlekelwa okudalwe ukuguquguquka. Ukuhlushwa kwe-ammonia kwahlulelwa ngephunga. Izinga elijwayelekile lokwengezwa ngu-0.06ml/L we-ammonia (amandla adonsela phansi athize 0.880 ) ngehora .

Brightener Cu-203B

Ukukhanya nokucaba kwe-coating kugcinwa ngokwengeza njalo i-Cu-203 B brightener ne-ammonia. Kungcono ukuyengeza ngokuzenzakalelayo. Okubili kungaxutshwa ngesilinganiso esifanele bese kuhlanjululwa izikhathi ezingu-10 ngaphambi kokungeza okugeza. Uma uhlanza, qiniseka ukuthi uhlambulula ngamanzi akhishwe nge-deionized.

I-Brightener yengezwa izikhathi ezingu-2 kuya kwezi-3 ngokushintsha komsebenzi ngamunye , 0.1-0.2ml/L isikhathi ngasinye ukuze kugcinwe ukukhanya kwe-coating. Ukwengezwa okuphelele kwansuku zonke kuncike enanini lezingxenye ezipuletiwe. Kubalwa ngokuya ngomthwalo omncane, izinga lokusetshenziswa licishe libe ngu-2L ngamahora ayi-10,000 ampere. Ukwengezwa okwengeziwe kuvame ukwenziwa ngezimpelasonto noma ngesikhathi samahhala.

I-ejenti yokuvula i-Cylinder Cu-203A

Isetshenziswa ngemva kokuba uketshezi lokugeza nokugeza luhlanziwe, futhi ngokuvamile aludingi ukulungiswa.

pH

I-pH kufanele ilawulwe ngaphakathi kwebanga elingu-8.6-9.2 , futhi kufanele ihlolwe njalo nge-electronic meter pH noma iphepha lokuhlola i-pH.

I-pH izonyuka kancane phakathi nenqubo yokwenziwa kwe-electroplating, futhi u-10% we-sulfuric acid oxutshwe ne-sulfuric kwengezwe ukuyinciphisa. Ngemva kokwengeza i-ammonia noma usawoti omkhulu, phinda ulinganise inani le-pH yokugeza .

3. Inqubo yokugeza

Ukulungiswa kwethangi

Lapho usebenzisa ithangi elisha, sebenzisa ipulasitiki ekhethekile njenge-Vulcron. Ngaphezu kwalokho, ithangi kufanele lifakwe i-alkali (NaOH 10g/L) amahora angu-8 kuya kwangu-12. Phakathi nale nqubo, izinga lokushisa lesisombululo se-alkali kufanele ligcinwe ku-50-60 ℃, futhi lihlungwe.

Uma ithangi eline-nickel-plated lisetshenziselwa ukuguqula inqubo yethusi ye-coke, sicela usebenzise le nqubo elandelayo.

1 . Sebenzisa amanzi ashisayo ukuze uhlanze ithange kanye nezinto ezisetshenziswayo eziseceleni, okuhlanganisa okokuhlunga, amathangi okulungisa, njll.

2. Cwilisa ithangi lokucwenga, engeza u-20g/L we-sulfuric acid ehlanjululwe kanye no-2-3g/L wekhabhoni ecushiwe, gcina izinga lokushisa liku-60 ℃, bese ugovuza okungenani amahora angu-8.

3. Khipha i-asidi bese ugeza ithange kanye nezinto ezisetshenziswayo eziseceleni kwamanzi ngamanzi.

4. Gcoba ithange lokucwenga kanye nezinto ezisetshenziswayo ezizungezile ngesisombululo esingu-1% NaOH ( 10g/L), gcina izinga lokushisa liku-50-60 ℃, futhi cwilisa okungenani amahora angu-12.

5. Khipha isisombululo se-alkaline bese ugeza ngamanzi. Lungiselela ithangi.

umuthi

range

| best value |

Anhydrous potassium pyrophosphate SF41588 |

230-270g/L |

| 25 0 g/L |

Copper pyrophosphate trihydrate SF41297 |

65-75 g/L |

| 70 g/L |

Amonia ( 0.880 sp.gr. ) |

3-5ml/L |

| 4 ml/L |

Cu-203A isilinda esivula isilinda |

2-3 ml/L |

| 2.5 ml /L |

Cu-203B brightener |

0.2-0.4 ml/L |

| 0.25 ml/L |

Slot match match |

Lapho ulungisa uketshezi lwethangi , uma izinga lamanzi endawo liqinile, kungcono ukusebenzisa amanzi athambile. Ngokuvamile amanzi akhiwe deionized asetshenziselwa ukwakha indawo yokugeza. |

Inqubo yokufaka enconywayo imi kanje:

1.Faka amanzi (40-50 ℃) cishe kumthamo wethangi elingu-1/2, engeza i-potassium pyrophosphate ngaphansi kokunyakaziswa yenze ichitheke ngokuphelele.

2.Yengeza i-pyrophosphate yethusi edingekayo, okufanele yengezwe ngamaqoqo ngokugoqoza ukuvimbela izinga lokushisa likhuphuke ngokushesha.

3.Ngemva kokuba i-pyrophosphate yethusi isihlakazeke ngokuphelele, engeza amanzi abandayo izinga lokusebenza, lungisa i-pH ibe ngu-8.6 ngo-50% we-dilute sulfuric acid, futhi inani le-sulfuric acid egxilile akufanele lidlule u-2.5ml/L. Pholisa uketshezi lwethangi ku-50-55 ℃, engeza amanzi e-ammonia adingekayo.

4.I-ammonia (i-gravity ethize 0.880 ) kufanele ihlanjululwe ngaphambi kokuba yengezwe kubhavu. Zungezisa ukucwenga kuze kucace uketshezi lwethangi.

5.Engeza isivulasi silinda esidingekayo se-Cu-203A, sihlambulule izikhathi ezingu-10 ngaphambi kokusingeza ethangini.

6.Engeza isicwebezeli se-Cu-203B esidingekayo, le nto iyakwenza. akudingeki ukuthi ihlanjululwe ngaphambi kokwengeza.

7.Qinisekisa kabusha inani le-pH, uma kudingeka, lilungise libe ngu-8.6 ngaphambi kokuyisebenzisa.

4. Izisetshenziswa

Trough

Kutuswa ukusebenzisa ulwelwesi lwe-PVC noma ulwelwesi lwerabha.

Amathangi asetshenziselwe ukwenza i-nickel ecwebezelayo noma ithusi elineasidi kufanele aphathwe ngalezi ziphakamiso ezingenhla lapho kwakhiwa indawo yokugeza.

I-heater

Sebenzisa i-titanium noma i-quartz immersion heater kagesi. Uma usebenzisa i-heater, uketshezi lokugeza kufanele lunyakanyiswe ngomoya. Ukwengeza, qiniseka ukuthi izinga loketshezi livamile futhi iheater icwiliswa ngaphansi kwezinga eliwuketshezi.

I-heater kufanele ihlanzwe njalo ukuze kukhishwe ifilimu eyakheke ku-quartz ngesikhathi senqubo ye-electroplating.

filtha

Isihlungi sifakwe ne-Dispak Filter Pads M.30713 noma izikhwama zesihlungi se-polypropylene. Uma usebenzisa izikhwama zokuhlunga, usizo lokuhlunga I-Filter Aid Powder N.41352 lungcono. Ezindaweni ezinekhwalithi yamanzi aqinile, kunconywa ukuthi uhlunge ngokuqhubekayo ku-1Turn ngehora. Ngokuvamile, ukuhlunga okuvamile kuphela kuyadingeka. Uma kuvela ukungcoliswa kwemvelo okuncane noma kusolwa, sebenzisa ikhabhoni ecushiwe i-Zonax ukuze ugaywe kabusha futhi uhlunge amahora ambalwa ngaphambi kokusetshenziswa.

I-Air agitation

Ithangi lokucwenga kufanele lifakwe ishubhu lepulasitiki elinyakazisa umoya. Lapho usebenza ngenani elikhulu lamanje, sebenzisa ukushuba komoya okuqinile. Ngaphansi kwezidingo ezikhethekile zezinto zokusebenza, i-cathode swing ingasetshenziswa.

anode

Kunconywa ukusebenzisa i-OFHC yethusi anode. Uma kungenjalo, i-oval electrolytic copper anode ingasetshenziswa esikhundleni salokho. Isilinganiso sendawo ye-anode kuya ku-cathode simayelana ne-1.5: 1, futhi umthamo wamanje we-anode ngu-1.6-3amp / dm 2. I-anode surface kufanele igcinwe ihlanzekile. Uma kukhona ifilimu ewugqinsi futhi ehlakazekile kubhavu, kusho ukuthi ukuminyana kwamanje kwe-anode kuphansi kakhulu.

5. Inqubo yokwelapha kusengaphambili

PyroMac ayikwazi ukusetshenziswa ngokuqondile kunsimbi noma ku-zinc die-cast substrates. Ngokuvamile i-copper cyanide noma i-nickel isetshenziswa njenge-primer, kodwa ingasetshenziswa ngokuqondile kunqubo ye-Bondal yokucubungula i-aluminium .

Inqubo enconywayo yensimbi:

Inqubo ephakanyisiwe ye-zinc die casting:

| 1. Ukucwiliswa kwe-thermal degreasing |

1. Ukucwiliswa kwe-thermal degreasing |

| 2. I-Anode electrolytic degreasing |

2. I-Anode electrolytic degreasing |

| 3. Ukugeza kabili |

3. Ukugeza kabili |

| 4. Ukucwiliswa kwe-asidi ( HCl ) |

4. I-asidi eqinile |

| 5. Ukugeza kabili |

5. Ukugeza kabili |

| 6. I-Flash copper plating ( Coprax noma Zonax ) |

6. I-Flash copper plating ( Coprax noma Zonax ) |

| 7. Noma i-flash nickel |

7. Ukugeza kabili |

| 8. Ukugeza kabili |

8. I-PyroMac Plating |

| 9. I-PyroMac Plating |

6. Ukuxazulula izinkinga |

| 1.I-gloss empofu

|

|

( A ) Isicwebezeli se-Cu-203B asanelanga, engeza u-0.2ml/L we-brightener .

( B ) Uma okuqukethwe kwe-ammonia kunganele, engeza amanzi e-ammonia 2ml/L , kodwa kufanele ahlanjululwe ngaphambi kokwengeza.

( C ) Ngokungcoliswa kwe-cyanide, engeza u-1.25ml/L we-hydrogen peroxide ukuze ulashwe. Nciphisa i-hydrogen peroxide ngaphambi kokuyengeza, bese usebenzisa ukunyakazisa umoya ukuze uhlakazeke ngokulinganayo ethangini. Uma kusetshenziswa ukugeza kwe-copper cyanide, kunconywa ukusebenzisa ukwelashwa kwe-H 2 O 2 kanye ngesonto.

Yehlisa ukukhishwa kwe-cyanide ukuze unciphise ukungcoliswa kwe-cyanide.

2.Icwebezelisi elimpofu endaweni ye-low density yamanje

( A ) Izinga lokushisa liphezulu kakhulu, yehlisa izinga lokushisa.

( B ) Amanzi amaningi e-ammonia, akhuphule izinga lokushisa ukuze avuse amanzi e-ammonia (izinga lokushisa kufanele lehliswe libuyele ebangeni elivamile lokusebenza ngaphambi kokuphinda lisetshenziswe).

( C ) P 2 O 7 4- iphansi kakhulu, hlola ukwakheka.

3. Ukushisisa endaweni yamanje ephezulu

( A ) kuncane kunokuvuthela, kanye nokuqhuma okunamandla, lungisa ukuma kwepayipi.

( B ) Izinga lokushisa liphansi kakhulu, lungisa izinga lokushisa.

( C ) P 2 O 7 4- iphansi kakhulu, hlola ukwakheka.

4.I-Coating enyathelwe noma enyakaziswayo endaweni yamanje ephansi

Uma i-ejenti yesicwebezelisi idlulele, uma ingaphezudlwana nje kancane, khulisa izinga lokushisa, uqinise ukuqhuma, futhi ukhuphule ukuminyana kwamanje kwe-electroplating. Indlela esheshayo ingangeza u-2.5ml/L we-Cu-203A cylinder opener (kodwa uma indawo yamanje ephansi isivele imnyama kakhulu, ungangezi).

Uma inani elikhulu le-Cu-203B brightener lengezwa ngephutha, kuthathwa njengokungcoliswa kwemvelo, futhi ikhabhoni ecushiwe isetshenziselwa ukuyihluza.

5.Ukungcola kwe-Organic

Ukwelashwa kwesihlungi se-carbon esicushiwe, bese wengeza i-1.2ml/L Cu-203A cylinder opener kanye ne-0.25ml/L Cu-203B brightener . Uma ukugeza kusetshenziswa u-1g/L wekhabhoni ecushiwe enqubweni yokucubungula iqoqo, ama-cylinder avulekile kanye nesicwebisi kuyasetshenziswa, ukuze okokugeza kufakwe kabusha ngesilinda esivulekile.

6.Chromium pollution

Ukungcola kwe-chromium Hexavalent bangela "izindawo zenkungu" ezingajwayelekile ebusweni bengubo. Ngakho-ke, lokhu kungcola kufanele kugwenywe.

Abathintwayo bama-hangers amabi noma izinto ezilungiswayo bazongenisa i-chromium futhi bangcoliswe. I-electrolysis ebuthakathaka ingenziwa. Ukuminyana kwamanje kwe-anode ngu-1amp/dm 2, okunganciphisa i-chromium ene-hexavalent ibe yi-trivalent.

Hexavalent chromium pollution will cause irregular "fog spots" on the surface of the coating. Therefore, this pollution must be prevented.

The contacts of bad hangers or fixtures will bring in chromium and be contaminated. Weak electrolysis can be implemented. The anode current density is 1amp/dm 2 , which can reduce hexavalent chromium to trivalent.

Imikhiqizo

Imikhiqizo